In 1870, Thomas Potterton (born 1847) took over the general contractor business his father (also Thomas Potterton) had established in Balham, South West London in the 1850s.

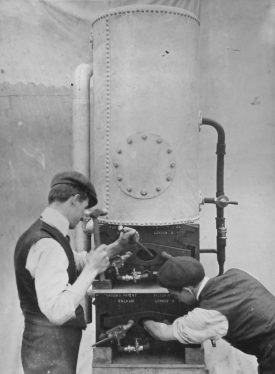

By 1894, Thomas Potterton had invented the ‘Zig-Zag’ boiler and had patented designs for improvements in boilers for heating greenhouses and similar structures. Further innovations and successes followed.

After Thomas Potterton’s death in 1926, the business was carried on by his sons Albert B. Potterton and Thomas F.C. Potterton, who became partners in Thomas Potterton (Heating Engineers) Limited. The business continued to innovate in boiler design, registering patents in the 1920s and 1930s. In 1937, Potterton boilers received a prestigious commission to install boilers at No.10 Downing Street when Neville Chamberlain was Prime Minister.

Works at Warwick

In 1944, the firm was taken over by De La Rue (Plastics) Limited. A shortage of skilled foundry men as well as production capacity led to the purchase of Portabello Works on Emscote Road in Warwick and boiler production was switched from London to Warwick in 1945.

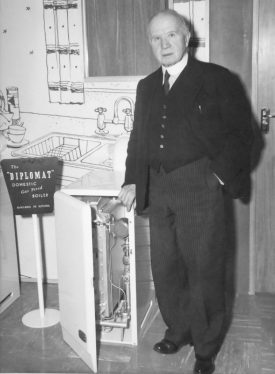

The company launched the ‘Diplomat’ gas fired and ‘DOA’ oil fired boiler series in 1955, which were particularly successful due to a succession of cold winters. The firm stopped installing boilers in 1957, deciding instead to concentrate on manufacturing and marketing. Future installation of boilers would be undertaken by Potterton approved installers.

In 1958, the firm became known as Thomas Potterton Limited and trading figures reached a record high. In this year, the purchase tax on boilers (introduced in 1947) was abolished, helping sales to increase. In September 1961, over 1,000 boilers were despatched in one week for the first time in the history of the company.

The company became Potterton International Limited in 1964 and opened a new office block in Warwick. Their first television commercial was broadcast on Boxing Day that year. Potterton produced their one millionth boiler a few years later in 1969 and launched the wall-hung cast iron boiler the same year.

Move to Warwickshire

Brooks House in Coventry Road, Warwick was officially opened in April 1971. The building, named after Ernest George Brooks (former Chairman and Managing Director), accommodated the Parts Department, Training School and Product Evaluation Department alongside sales and service offices. In 1974, Potterton finally left Wandsworth and moved all their remaining functions and manufacturing up to Warwickshire.

The 1970s saw an increase in the number of UK households with gas central heating. By the late 1970s, Potterton were manufacturing an average of around 3,000 boilers a week.

During the 1980s, Potterton based its manufacturing and administrative activities in Warwick, having a second assembly plant in Rugby and regional sales and services offices in Warwick, Wandsworth and Otley. At this time, Potterton employed around 1,200 employees, mainly based in Warwick.

Structural change

Birmid Qualcast Limited had bought the Potterton business from De La Rue in 1973 and in 1988 was itself acquired in turn by Blue Circle Industries PLC. Blue Circle likewise acquired the Myson Group in 1989/90. Myson had been established in the 1950s and, like Potterton, manufactured and sold domestic gas and oil boilers.

Baxi purchased the Blue Circle Heating Division in 1999 and Potterton are still part of Baxi Heating today.

Select Bibliography

Records of Potterton, Boiler Manufacturers, Warwick held at Warwickshire County Record Office references CR3861 and CR4765.

Grace’s Guide, British Industrial History, (for information on Thomas Potterton, Thomas De La Rue and Co., Birmid Qualcast, Birmid Industries, Qualcast, Blue Circle and Myson).

Potterton website, (especially ‘About Potterton’ and ‘Potterton history’).

Roberts, Brian, ‘Pioneers: Thomas Potterton 1847-1926’ (CIBSE Heritage Group Electronic Publication via the Heritage Group Website for the Chartered Institution of Building Services Engineers).

Comments

My father was toolroom foreman at Potterton’s Warwick for over 20 years .One of his former apprentices Greg Etter ( wrong spelling no doubt) Became general manager at one stage.

Prior to that my father was at industrial mouldings , at one time making the prototype orange reflectors for push bike pedals ,patented by Jon FINK of Fink productions and Leamington Plating companies

Add a comment about this page